Outsourcing Excellence: CNC Machining Solutions

CNC machining, vital in modern manufacturing, is recognized for its exceptional precision and operational efficiency. Forecasts indicate that the CNC machine market will significantly grow, reaching an estimated $128.86 billion by 2026. This growth, at an annual rate of 5.5% from 2019 to 2026, signifies CNC machining’s increasing importance in the industrial sector.

With a rapidly expanding market and a plethora of technological advancements shaping the CNC machining landscape, businesses are poised to tap into this burgeoning field. Let’s embark on a comprehensive journey to understand how outsourcing CNC machining can be a game-changer for companies striving to excel in today’s manufacturing world.

Evaluating Your CNC Machining Needs

The first step in successful CNC machining outsourcing is to evaluate specific project requirements. This involves a thorough analysis of the complexity, volume, and materials involved in your project. Clear specifications and goals are crucial for aligning the services of your CNC machining partner with your business needs.

Understanding these factors ensures that the outsourcing decision enhances, rather than hinders, your production capabilities. In this context, rapid prototyping quotes are not just numbers; they represent the efficiency of transitioning from design to tangible models. This process allows for immediate physical assessment of design, functionality, and manufacturability, effectively reducing development time and costs while ensuring precision and quality in the final product. Rapid prototyping, therefore, plays a critical role in evaluating and refining CNC machining needs to ensure the final output perfectly aligns with project requirements.

Choosing the Right CNC Machining Partner

Selecting an outsourcing partner is a decision that can make or break a project. Key criteria include the provider’s track record, technological capabilities, and certifications. A partner with advanced technology and a strong portfolio ensures that your project is handled with the required expertise and precision. The industry’s growth, reflected by the expected increase in the global CNC machine tools market from $25.34 billion in 2022 to $26.83 billion in 2023, indicates a competitive and evolving landscape where choosing the right partner is crucial.

Cost-Effectiveness of Outsourcing CNC Machining

The financial benefits of outsourcing CNC machining extend beyond simply avoiding high initial investments in machinery and specialized staff, it also offers an operational advantage. By outsourcing, businesses can convert fixed overheads into variable costs, creating more elasticity in their financial planning. This adaptability is crucial in a market characterized by rapid technological shifts and varying customer demands.

Additionally, outsourcing CNC machining means companies can focus on their core competencies while leaving specialized manufacturing tasks to experts, potentially leading to better resource allocation and efficiency in production. This strategic move not only conserves capital but also streamlines operations, potentially leading to a more agile and financially healthy business model.

Quality Assurance in Outsourced CNC Projects

Maintaining high-quality standards is a paramount concern in outsourcing CNC machining projects. This involves adhering to industry standards, conducting rigorous testing, and maintaining consistent communication with the outsourcing partner. Regular updates and clear communication channels are essential to ensure that the project meets the desired quality benchmarks.

Navigating Lead Times and Delivery Schedules

Effectively managing lead times and delivery schedules is critical in CNC machining outsourcing. This process demands strategic planning and thorough coordination with the outsourcing partner to strike a balance between speed, quality, and cost. Mastery of the time-quality-cost triangle is essential to ensure on-time delivery without sacrificing quality. Additionally, it’s crucial to establish clear communication channels and set realistic expectations with the provider.

This approach allows for flexibility to adapt to unforeseen delays or changes, ensuring a smoother workflow and maintaining the integrity of the final product. Understanding these dynamics is key to navigating the complexities of lead times and delivery schedules in outsourcing.

Future Trends in CNC Machining Outsourcing

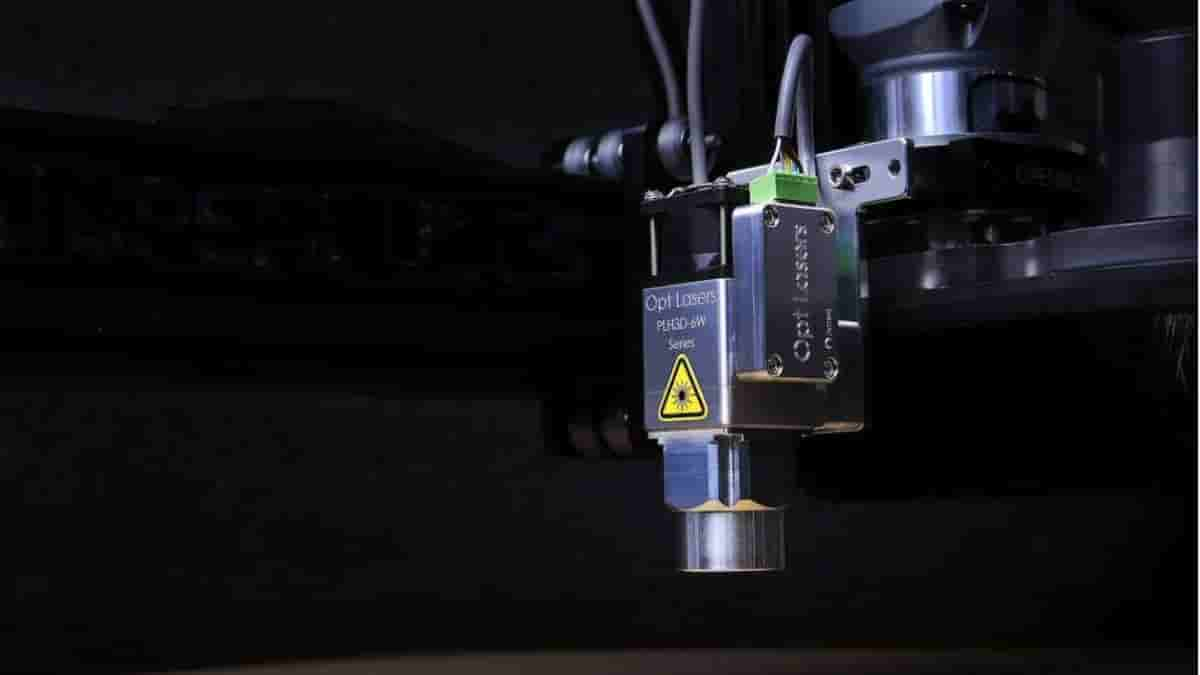

The CNC machining sector is witnessing rapid transformations due to technological innovations. As businesses consider outsourcing their CNC machining requirements, understanding these evolving trends becomes critical. Key areas shaping the future include the integration of artificial intelligence and automation, which promise enhanced efficiency and accuracy. Additionally, advancements in software capabilities are revolutionizing how CNC operations are planned, executed, and managed.

Businesses must be proactive in using these technologies and flexible to preserve a competitive edge in this changing market. This method anticipates and becomes ready for potential advancements in CNC machining, rather than merely following the latest trends. Accepting these modifications is a strategic requirement for businesses seeking to outsource their CNC machining requirements, as they can result in notable enhancements to production processes, cost-effectiveness, and product quality.

Conclusion

Outsourcing CNC machining presents a strategic opportunity for businesses to enhance their manufacturing capabilities. By carefully evaluating needs, selecting the right partner, and staying ahead of industry trends, companies can achieve excellence in their CNC machining projects. Embracing outsourcing as a path to innovation and growth is essential in the rapidly evolving world of manufacturing.